More panel fabrication

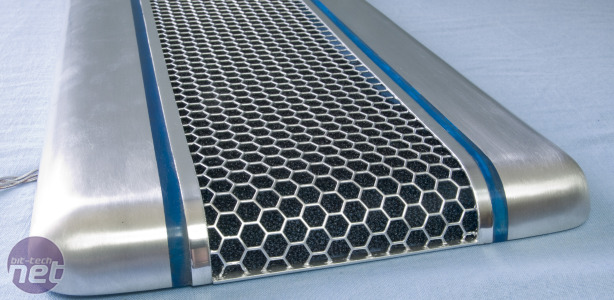

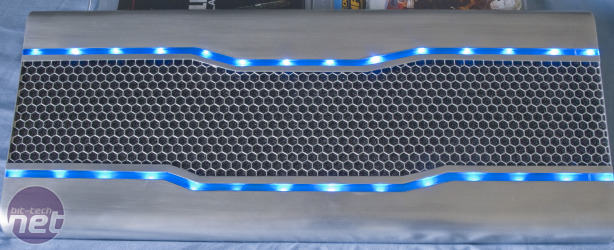

One of my favourite bits of eye candy during the build came after I joined both parts of the top and front door panel together using Honey Comb Mesh and black Open Cell foam. Each part was glued together using a large amount of JB Weld:

Click to enlarge

After the cast panels were complete the case began to take shape. The top cast panel was fixed into position using JB Weld and the front door panel was attached using anti friction hinges I made:

Click to enlarge

Click to enlarge

Side panel and radiator

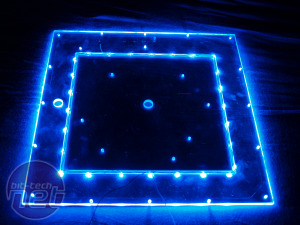

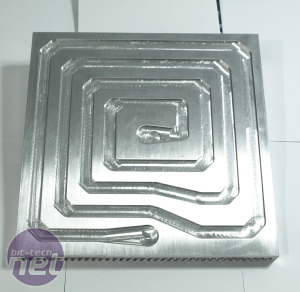

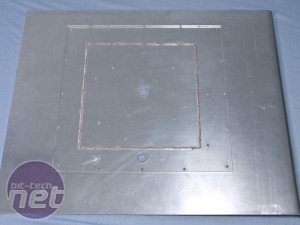

This part of the project changed considerably from the original design, this was due to my first radiator design being a little too ambitious for me to successfully produce. So I chose a simpler yet still visually pleasing alternative. I managed to purchase a large extruded aluminium heatsink which I milled a channel into and made a matching clear acrylic panel with O ring seal:

Click to enlarge

Click to enlarge

I then fabricated an aluminium side panel for the radiator, on which the holes were all drilled on the milling machine and the curved section was produced by using a rubber mallet to bend the aluminium around a pole.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.